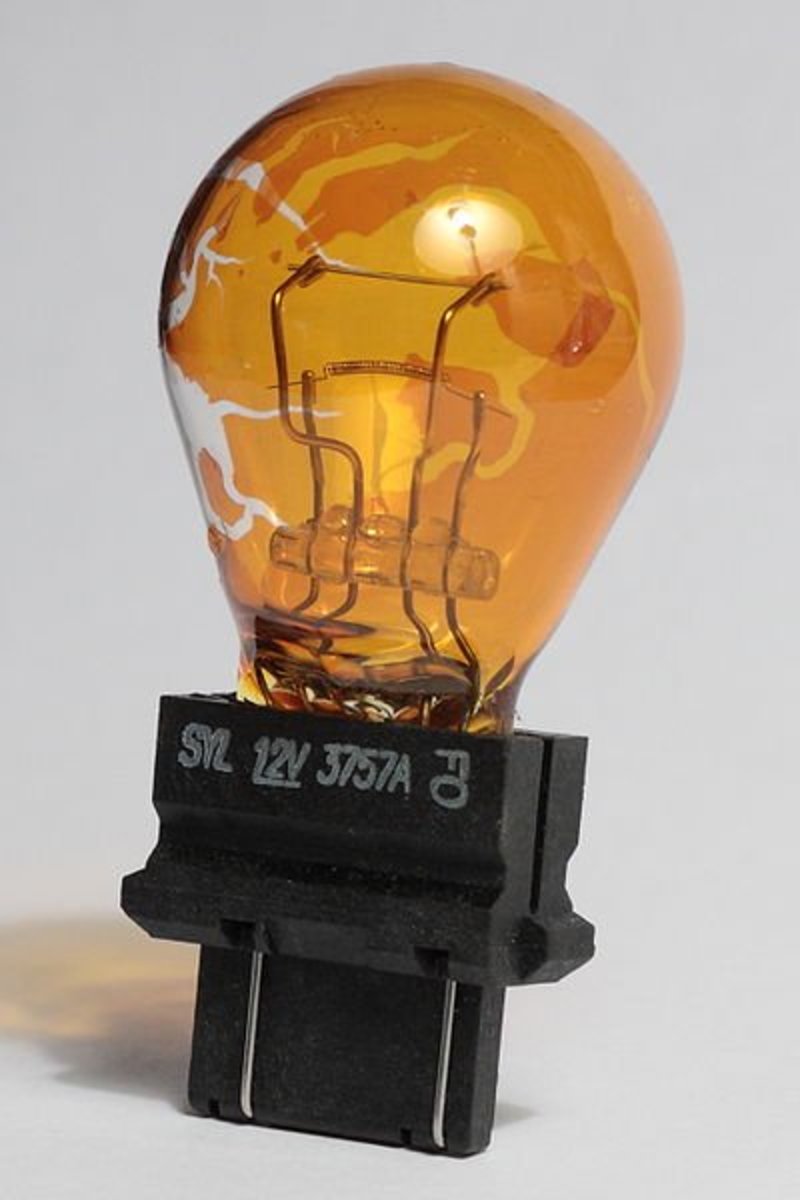

When a vehicle arrives with turn signal problems, professional technicians begin with a thorough visual inspection. They check the bulbs, wiring, fuses, and the turn signal switch for any obvious signs of damage or wear. Burned-out bulbs or broken wires are common culprits and can often be identified quickly during this step. Technicians also look for corrosion around bulb sockets and connectors, as moisture buildup can disrupt electrical flow. This initial inspection helps narrow down the possible causes before more detailed electrical testing is performed.

Using Diagnostic Tools

After the visual check, technicians use specialized diagnostic tools to further investigate the electrical system. A multimeter is commonly employed to measure voltage, continuity, and resistance in the turn signal circuits. This helps detect any breaks in wiring or faulty components that aren’t visible to the naked eye. Additionally, some modern vehicles come equipped with onboard diagnostic systems that can provide error codes related to lighting issues. Technicians connect diagnostic scanners to the vehicle’s computer to retrieve these codes, guiding them to the exact source of the malfunction.

Testing the Turn Signal Relay

The turn signal relay controls the blinking function of the indicators and is a frequent source of failure. Technicians test this component by checking its operation with a multimeter or by temporarily replacing it with a known working relay. If the signals start blinking correctly after swapping the relay, the faulty part is identified and replaced. Because the relay is often located in the fuse box, it is an accessible and relatively straightforward component to test and change.

Examining the Turn Signal Switch

If the bulbs, wiring, and relay check out fine, the technician moves on to inspect the turn signal switch located on the steering column. This switch is more complex and may require partial disassembly of the steering column area. Technicians use electrical testers to verify that the switch sends the correct signals when activated. Symptoms like signals not turning off or only working intermittently often indicate a worn or defective switch. Identifying switch faults typically requires professional experience and tools due to the switch’s integration with other steering and electrical systems. Opting for the Auto Repair in Savannah, GA based service would be quite a matter.

Final Verification and Repairs

Once the faulty component—whether a bulb, relay, wiring, or switch—is identified, the technician proceeds with the repair or replacement. After fixing the issue, they perform a final test to ensure the turn signals function properly on both sides, including checking hazard lights and any linked warning indicators on the dashboard. This comprehensive approach guarantees that the repair is successful and the vehicle is safe to drive. Technicians may also advise customers on maintenance tips to prevent future turn signal problems.

Conclusion:

Diagnosing turn signal failures involves a step-by-step process combining visual checks, electrical testing, and component-specific assessments. Professional technicians use their expertise and specialized tools to accurately pinpoint issues, from simple bulb failures to complex switch malfunctions. This thorough diagnostic approach ensures reliable repairs, keeping your vehicle’s turn signals functioning properly and maintaining safety on the road.